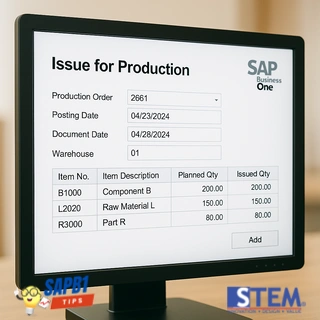

Issue for Production is a critical step in the production process in SAP Business One. This step is used to release raw materials from the warehouse to the production process. Below is an explanation of how to create an Issue for Production.

Requirements and Conditions for Creating Issue for Production

Several factors need to be considered before performing an Issue for Production:

- Production Order Status

Only Production Orders with the status Released can proceed to the Issue for Production process. If the status is still Planned, the system will not allow the creation of this document. Production Orders with the status Closed cannot undergo Issue for Production. - Issue Components Method

To perform Issue for Production manually, ensure that the components in the Production Order details use the Issue Method: Manual. This method can be configured on the Components tab within the Production Order document. If using the Backflush method, the system will automatically perform Issue for Production during the Receipt from Production transaction.

Accessing the Issue for Production Menu

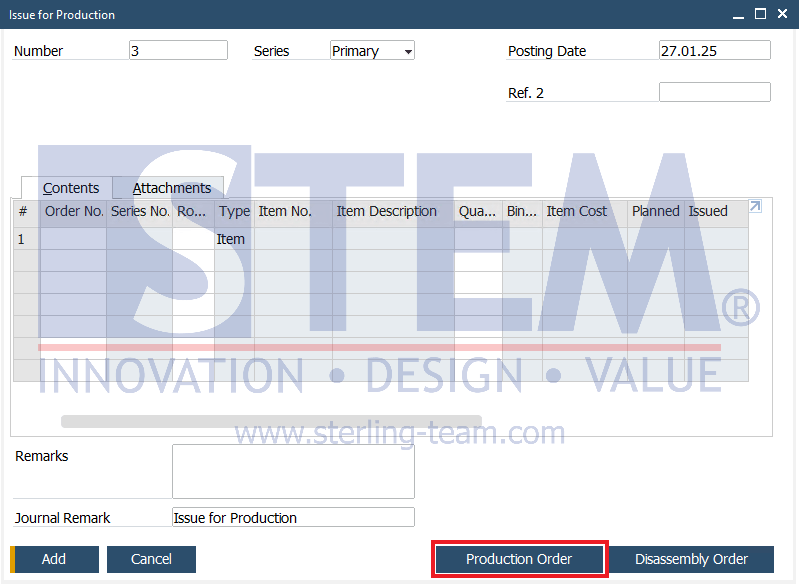

There are two main ways to create an Issue for Production in SAP Business One:

- Through the Production > Issue for Production Menu

- Open the Production menu on the main panel of SAP Business One.

- Select the Issue for Production

- Click the Production Order button, then select the Production Order document to process for the Issue for Production.

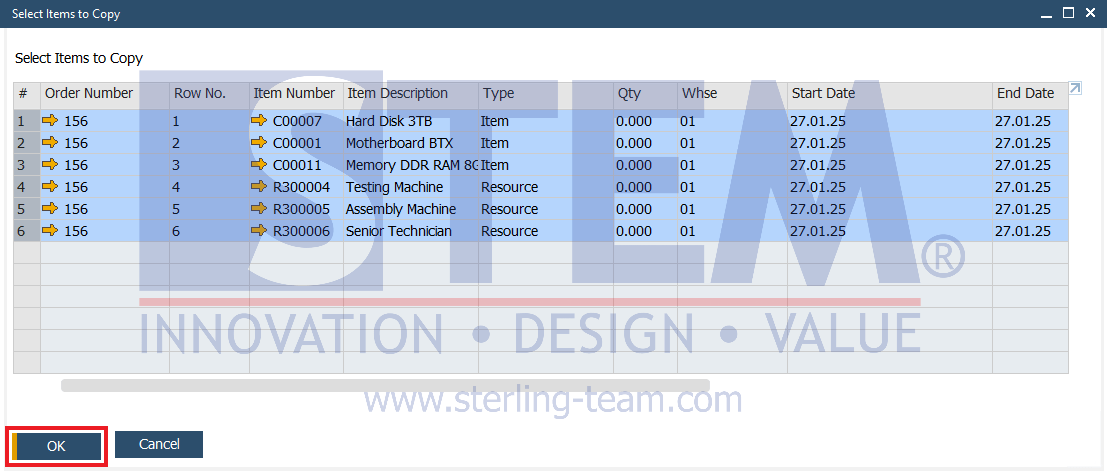

- A Select Items to Copy window will appear. Choose the components (items or resources) to issue. You can select multiple components at once.

- Through the Production > Production Order Menu

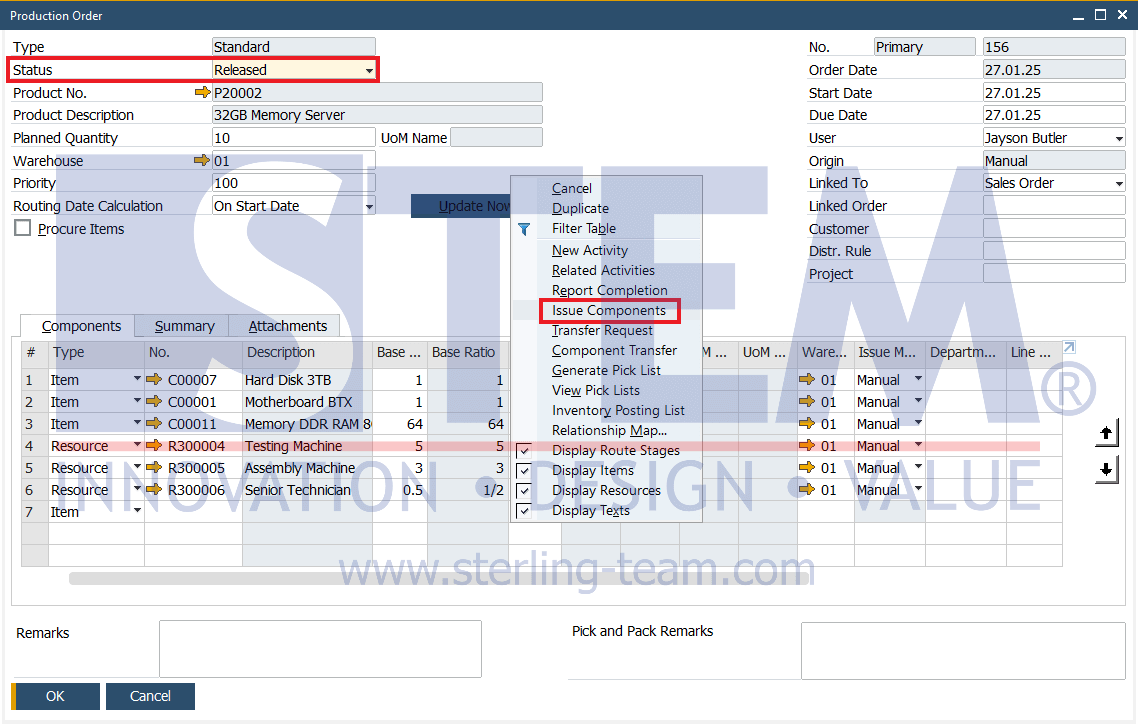

- Open the Production menu and select the Production Order

- Find and select the Production Order document with the status Released, that will undergo Issue for Production.

- Right-click on a blank area within the Production Order document and select the Issue Components

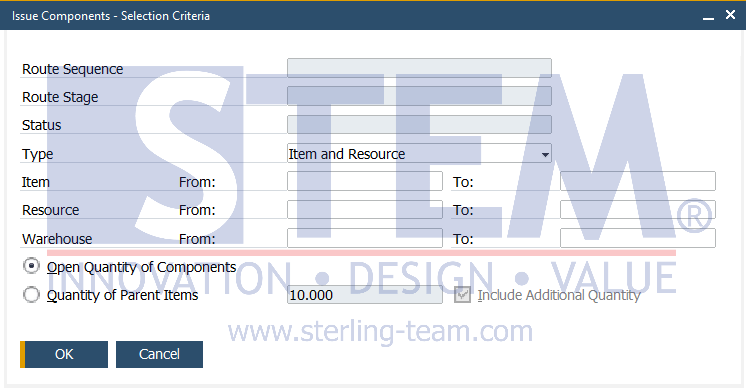

- The Issue Component – Selection Criteria window will open. In this window, users can select the criteria for the components to be issued based on Item, Resource, or Warehouse. There are options available to determine the quantity of components to be issued, which are:

- Open Quantity of Components: This option is used to release the remaining quantity (open quantity) of components as needed in the Production Order.

- Quantity of Parent Items: This option is used to determine the component quantity based on the number of parent items being produced.

- After selecting the appropriate criteria, click OK to proceed. The Issue for Production window will open with component details matching the selected criteria.

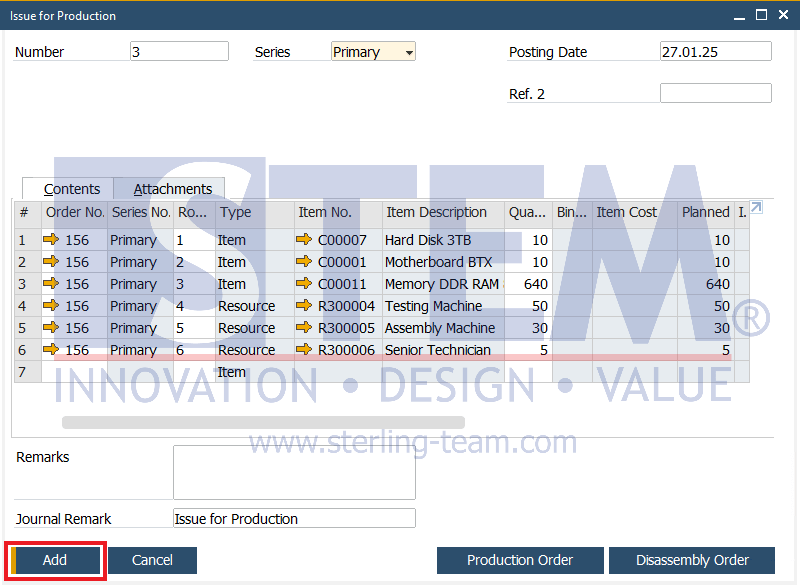

Review and Save the Issue for Production Document

- Once all the data is entered in the Issue for Production document, double-check that the components to be released align with the requirements listed in the Production Order.

- Verify the quantity of each raw material and adjust if necessary.

- Click the Add button to save the document and complete the process.

The Issue for Production process in SAP Business One ensures that raw materials are available and ready for production. By following the steps outlined above, you can ensure this process runs smoothly and meets the production needs of your company. Always verify that the data in the Production Order document is accurate and that raw material stock is sufficient before performing Issue for Production.

Also read:

- Production Issue Method: Backflush vs Manual

- How to Return Components Have Been Used in a Production Order

- By-Product in Production Documents

- How to Record Cost of Resources in the Production Process

- Production Standard (Std) Cost Rollup

- Custom Report – Query Production Order Planned and Released Summary