In the business world, inventory management is a key factor for operational smoothness. One crucial aspect of inventory management is ensuring that inventory levels do not fall too low, thus preventing the risk of running out of stock, which can hinder production and sales. The “Alert Minimum Stock Deviation” feature in SAP Business One is designed to provide warnings to users when the inventory of an item approaches or reaches a pre-defined minimum value.

Why is this important? Because maintaining inventory above the established minimum level is a crucial step in preventing stock shortages. When the inventory of an item approaches the minimum value, this alert provides an opportunity for management teams to take proactive actions, such as making additional purchases or planning further production, to prevent stockouts that could disrupt business operations.

With this warning, companies can optimize their inventory management, avoid potentially damaging stock shortages, and ensure the smoothness of production and sales. This feature helps improve operational efficiency and ensures that businesses can meet customer demands in a timely manner. The steps to be taken are as follows:

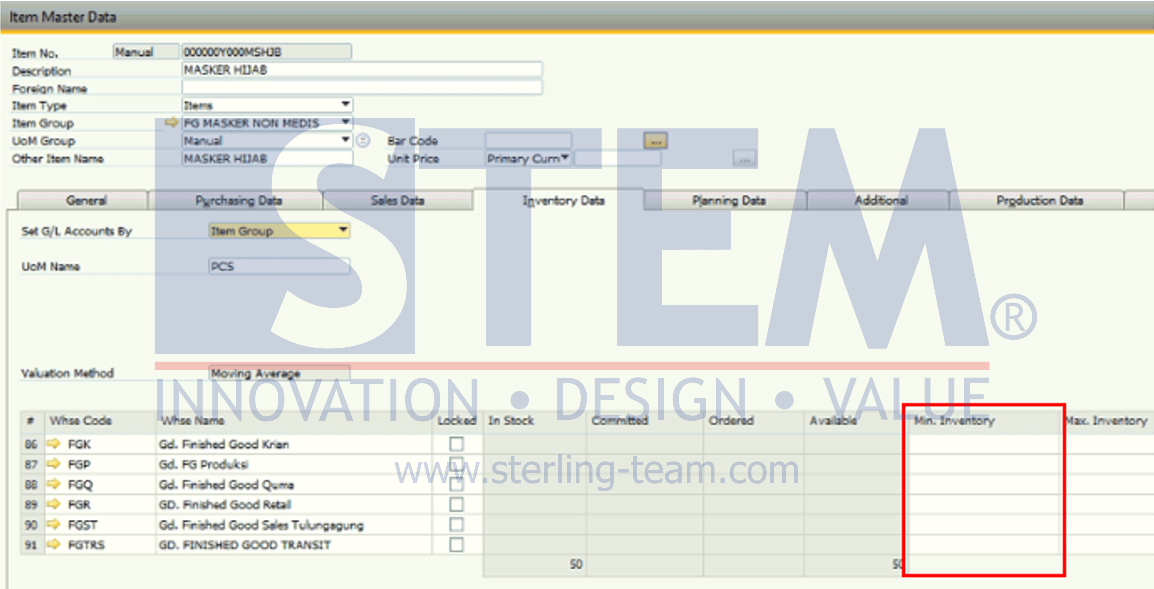

- Determine the Minimum Inventory per Warehouse in the Item Master Data (Inventory -> Item Master Data).

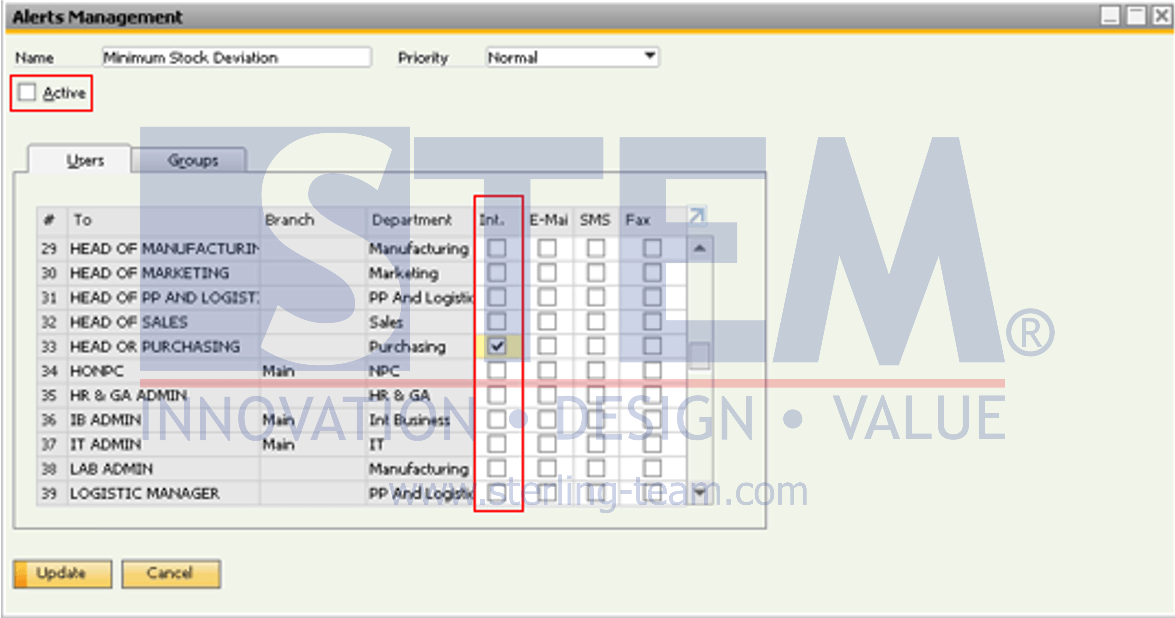

- Navigate to menu Administration -> Alerts Management. In the Alert Management view, choose Alert Status: All to display all alerts. Then select Minimum Stock Deviation by clicking on the gold arrow and check the Active box to activate the alert. Select the user to receive the alert/message when the stock in the warehouse falls below the Minimum Qty previously set in the Item Master Data. Then, click the Update.

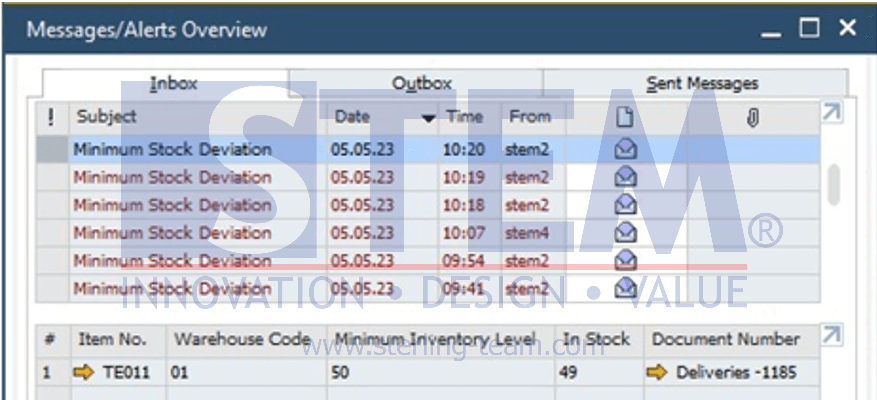

- Below is an example notification (alert) that users will receive.

Also read:

- Setup Warning for Inventory Exceeding Defined Range

- Alert Management Function in SAP Business One

- Using Query For Alerts

- Negative Inventory in SAP Business One

- Inventory Cycle on SAP Business One

- Automatic Availability Check Feature